Help me understand the correlation between boiler circulator RPM / HP / Head / Flow / System Pressure - see the particulars at the bottom.

CASE: My 1986 boiler came with Armstrong S25 circ (same as B&G 100). When the circ failed I replaced it in an emergency with the Taco 007. Now each time thermostat called for heat and the boiler kicked in I would hear 3-4 gentle pops from the boiler (within first 15 seconds, and never at other times). Someone here suggested lower head on the TACO 007 maybe the reason (24 vs 32). So I replaced the 007 with TACO 0010 (closest match to Armstrong S25). Sure enough the popping sounds are gone. But now water flow sound in pipes and rads is loud, and when the boiler heats up I am hearing a wailing sound. I can live with the water flow sound, but the wailing can be annoying. Why is the TACO 0010 causing the wailing? What part of the system can I adjust to stop it?

Cold system pressure has always been, and is now set at 12 PSI. When the boiler runs hot pressure rises to about 18 PSI.

PARTICULARS:

Cold system pressure: 12 / Height from gauge to the highest rad: 14 feet

Expansion tank: 12 PSI

Armstrong S25: 1750RPM; 1/12HP; 9-32 Flow-GPM (original system circ, was ideal setup)

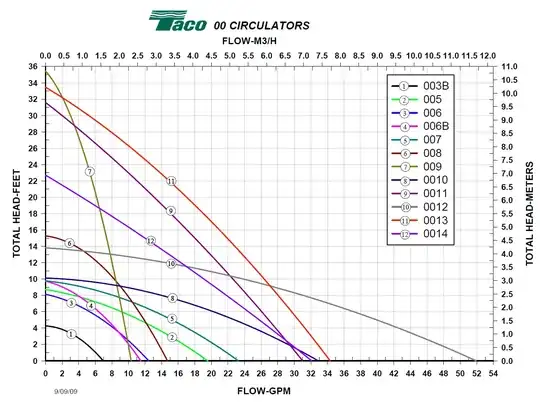

TACO 007: 3250RPM; 1/25HP; 10-24 Flow-GPM (problem: few pops after boiler startup)

TACO 0010: 3250RPM; 1/8HP; 10-33 Flow-GPM (problem: water flow sound + wailing when boiler heats up)