In my house there is a dryer outlet that, even though inconvenient to me (my dryer is 120V), I don't want to eliminate for house reselling reasons. As it was until now a 3 prong outlet, I have been connecting my dryer through an external box that I built, which is shown in the picture

External box that connects to the dryer outlet

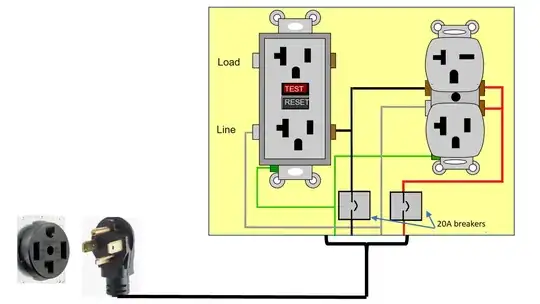

The box is fed by a dryer cable connected to the outlet that carries one hot and the neutral to a 20A GFCI outlet (the second hot conductor was terminated open in the outlet). I put a push-resettable 20A breaker (the push button is visible on the right side) between the hot conductor and the GFCI receptacle that allowed me to protect the box without having to mess with the breaker panel. This has allowed me so far to safely use my dryer without doing any permanent modifications that could result in NEC violations.

As I was recently able to add a grounding conductor to the dryer circuit, I am now envisioniing ways to modify my box into a "2-gang box" to make it more useful. The feeding will be through a 4-prong dryer cable attached to my new grounded outlet. On the left side I will keep the existing configuration (just adding the ground connection) while on the other side I am planning to insert a dual 120/240V 20A duplex receptacle that would allow me to use directly some 240V European appliances, getting rid of a bulky 3000VA step up transformer whose safety I don't fully trust.

My question is: can I do this in a safe way by just adding a second resettable 20A breaker to the other hot conductor, as shown in the scheme below?

The wires inside the box are 12AWG, with overcurrent in the two hots protected by two

Carling miniature 20A thermal circuit breakers, and the dryer circuit is protected in the panel by a Eaton BR 30A dual pole breaker. Being an external box, I am not concerned about the letter of the code, but I am of course concerned about safety.

The wires inside the box are 12AWG, with overcurrent in the two hots protected by two

Carling miniature 20A thermal circuit breakers, and the dryer circuit is protected in the panel by a Eaton BR 30A dual pole breaker. Being an external box, I am not concerned about the letter of the code, but I am of course concerned about safety.

I can think of at least a couple of issues on which I would like to get some advice. The first is the fact that the Carling breakers in the box are independent. If that was an issue, I believe it can be overcome by replacing the 30A dual pole breaker in the panel with a 20A one. The second is that the mixed 120/240V receptacle is not GFCI. However, it is grounded and GFCI is not a requirement for the 4-prong dryer outlet. This could be also be overcome by using a dual pole 20A GFCI breaker in the panel, but I woud gladly not spend the extra money if it was just an overkill.

Any advice, suggestion, critique is highly appreciated

NOTE: it would be great if I could find a duplex outlet with the 240V side having that universal shape that can directly accept European male plugs. Does anyone know if it is available?