I think this project of yours would be entirely feasible and I think you should try it.

There would be no appreciable difference in overall tension on the neck by replacing the thinner of each pair of strings with a duplicate of its lower-octave pair (or vice-versa). I've done the maths.

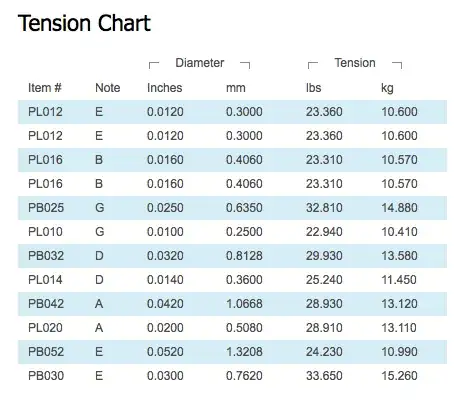

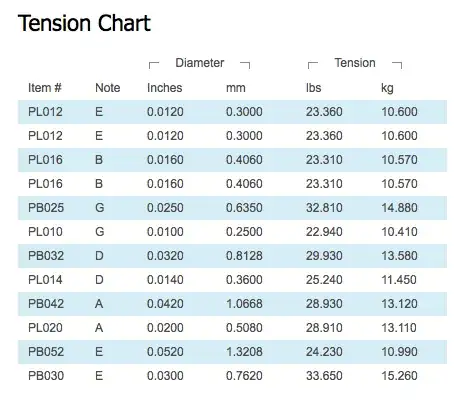

Here is a typical set of strings for an acoustic 12-string guitar, gauge 12 through 52, provided by D'Addario. The chart below lists the exact tension of each string when tuned to standard pitch.

http://daddario.com/DADProductDetail.Page?ActiveID=3769&productid=81&productname=EJ39_12_String_Phosphor_Bronze__Medium__12_52

The total tension on the neck for these string gauges at standard pitch adds up to 319.98 lbs or 145.14 kg.

If you were to take each pair of strings, remove the thinner higher octave string, and replace it with a wound lower octave string, the overall tension would only be 325.12 lbs or 147.47 kg. This is only a 1.6% increase in string tension.

You would probably not have to make any adjustment to the truss rod tension on the neck of the guitar to accomplish this.

What you would have to do is to pay a professional guitar repair technician to permanently modify the nut of the guitar to widen the slots that the strings fit into so that they would sit at the proper height. Furthermore this would be best attempted on a 12-string guitar that has a wide nut in the first place. Some 12-string guitars have a fingerboard width of 48mm, whereas others (the classic Rickenbacker electric for example) have a tremendously narrow fingerboard width of only 41.5mm.

The problem is that the extra low strings (which are wound and thicker in diameter) would need sufficient extra space between strings so that they could vibrate freely and would not clash into their neighbors while vibrating.

I think this could work if:

1) You have a guitar with a wide fingerboard

2) You have a guitar repair technician remove the original nut, set it aside and save it (so you could convert the guitar back to its original state later on)

3) You have the guitar technician cut an entirely new nut with the correct slot sizes and with a tiny bit of extra width between the string pairs. (You might have to be willing to let the technician try this several times with several blank nuts until he gets it right. Blank nuts are not expensive but the labor to shape and cut them is.)

4) You are willing to strum the guitar softly so that the strings don't clash into each other and create a lot of glitchy noise.

Overall I don't think any modifications to the bridge saddle would be necessary, but a guitar technician might say otherwise.

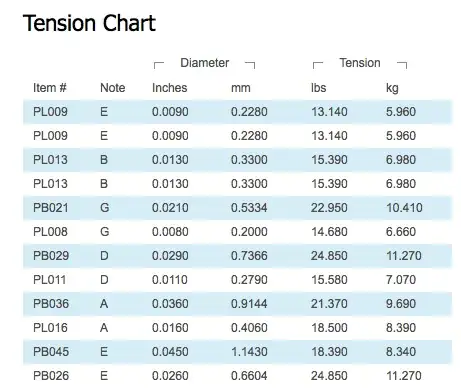

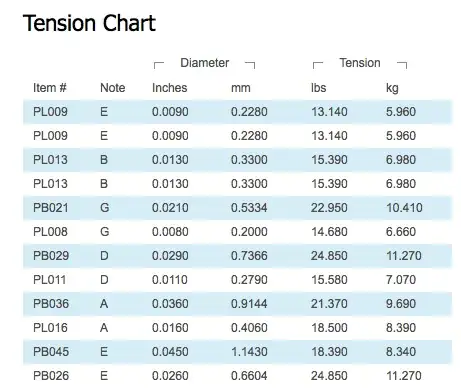

I have a further suggestion, however: Assemble a custom set of individual strings based on the lightest gauge set commonly available for a 12-string acoustic guitar. For instance, D'Addario has a set that goes from 9 to 45-gauge:

I would suggest trying this solely to minimize the problem of the pairs of lower-octave strings crashing together when strummed hard. The overall lower neck tension would not be the reason for my suggesting this. But in doing so, you will need a truss rod adjustment in addition to the replacement, custom-shaped-and-cut nut, to account for the much lower overall neck tension of this set.

In either case, this experiment should be entirely reversible by removing the new nut, replacing the original nut, re-stringing with the original gauge strings, and doing a truss-rod adjustment.

I think this would be a worthwhile experiment.

Footnote:

Stringing a 12-string guitar with unison pairs of strings is not a new idea. Many variations on this idea have been tried and are available from the Veillette guitar company in Woodstock, New York. (Click on the link.) Have a look at their various models (which are hand-built according to a customer's specifications and are very expensive.) If you have any specific questions about modifying your own guitar, I suggest that you contact Veillette and ask them for advice.