While I know how to operate a power drill in general (by the manual, so to say), I am wondering which things I should avoid of doing to it, in order to get the best out of the drill. I want to know about things that I might use a power drill for, because it seems like a genious idea, but which put the mechanics and electronics at danger. As an example: I see and am tempted to tilt the drill in a hole or apply perpendicular force on the drill bit as in milling. While I think this is a common idea and practice, I am not sure about how much damage this does to the drive, if at all.

-

3Here is an excellent example of how not to use a power drill, https://www.youtube.com/watch?v=dEU7ocjEza0 :) – hlovdal Jun 23 '16 at 19:47

-

1Avoid using it as a hammer (unless it's a hammer drill). – statueuphemism Jun 23 '16 at 20:22

-

Don't drill above yourself if you can help it. – Owen Johnson Jun 23 '16 at 20:34

-

Don't drop it from a ladder with a bit in it.. – Raystafarian Jun 24 '16 at 11:53

-

1@Tester101 - booo booo. Reopen this. Who cares if there are too many answers a lot of SE sites do canonical questions. You know you want to put an answer down with lots of pictures. – DMoore Jun 24 '16 at 16:45

-

@DMoore I do love me some pictures. If the question asked how to properly use a drill, it might be more useful. – Tester101 Jun 24 '16 at 17:38

-

@Tester - we shouldn't be closing a question with 2k hits. Rewrite it so it meets your standards. Then do your picture thing, you can even steal some of my answers :) – DMoore Jun 24 '16 at 17:40

-

@Tester101: I can find 1000 blog pages, videos and instructions on how to use a drill (put axial force, how to use the torque limiter, etc.). I don't need more information on that. I want to know what I should not use the drill for. Things that I might use them for but which puts the mechanics and electronics at danger. Try to find this with google, and what you'll find is this question on SE. ;-) – kamuro Jun 24 '16 at 18:25

-

2@kamuro I can think of an infinite number of things you should not do with a drill. If you know how to use a drill, what you shouldn't do doesn't matter. – Tester101 Jun 24 '16 at 18:49

-

@Tester101 - There are also an infinite number of things you can do with a drill. And for a lot of our questions on here damn close to an infinite amount of answers. – DMoore Jun 24 '16 at 20:00

-

In that case, I would like to add another valid answer you should NOT use a drill to comb your hair. – statueuphemism Jun 24 '16 at 21:21

-

@Tester101: I was talking about "things I might use them for, but which put the mechanics and electronics at danger". I would say that this question is easily answerable with only considerable answer-volume and in a form that does not strip answers from possibly valuable information. Regarding your last sentence: if I only ever stick to things I know are right I restrain myself from all things which might be good but I am uncertain if they might not be bad use. I can ask for each individual one or ask knowledgable ppl about what they know is common and bad use. That was my intention here. – kamuro Jun 25 '16 at 08:30

7 Answers

Some other helpful hints (not from Heloise)

0) ALWAYS wear gloves and eye protection. (Note: if you're using one hand to hold down the material being drilled, a glove can reduce injury if the drill bit jams. On the other hand, you should never depend on body parts to hold things in place)

1) When drilling into soft material such as plastic or pine, withdraw the bit periodically to clear out shavings.

2) When drilling into metal or hard materials, use a center punch to give you a starting hole. This avoids "wander" when you start up, and reduces the need to push down hard in an attempt to avoid "wander."

3) Don't put a gigantic size bit (e.g. spade or Forstner types) in a drill not designed for one. The torque required will burn out the motor.

4) Not bad for the drill, but bad for the bits: when using really small diameter bits, be careful and gentle or they'll snap. If you've got a 3-prong chuck, make sure the drill bit is properly centered before attempting to drill.

Note: it's fine to drill at an angle so long as the applied force is along the shaft of the drill bit.

- 3,917

- 13

- 14

-

9

-

@Tristan Would you rather a drill bit tore up a glove or your finger? – Carl Witthoft Jun 23 '16 at 17:11

-

8@Carl: I'd rather the drill bit didn't pull on the glove and make the glove tear off my finger. Read http://diy.stackexchange.com/a/11902/5556 and http://diy.stackexchange.com/a/4154/5556 – Lightness Races in Orbit Jun 23 '16 at 17:11

-

Yeah I would remove gloves from item zero. There's no benefit and possible harm. – Jasmine Jun 23 '16 at 17:16

-

1

-

Yeah I avoid gloves on pretty much anything except reciprocating saws, too risky and sometimes it reduces the tactile feedback that helps control it. I've had searing hammer drill bits break onto me and it's not too bad, as long as you have the eyes protected. Good answer! – Raystafarian Jun 24 '16 at 11:52

Just some things I see on jobs all the time:

Do not use a power drill (you want to keep mix things). You will blow out the motor in a good power drill by using it as a mixer. I see my guys use their Makitas with a mixing rod. And have seen many ruin them. I simply give them a 30 year old craftsman electric drill I have that I would give away for $5. It over heats after 5 mins but gets the job done. They also make specialty drills for mixing.

Your drill doesn't always (or hardly ever) needs to be set at the highest torque setting. When drilling it should be controlled. Doing it too fast, too much torque, will just give you a lot of stripped screws.

Buy good bits, whether this is actually drilling bits or bits used for screwing. It is such a low cost way to not only make your life easier but also make your drill last longer because it isn't being strained for no reason. This includes the right tips for drilling through wood, metal, plastics/others. This includes have a wide variety of bits that sink into your screws perfectly. If you use a slightly small bit on 2000 drywall screws you will spend a lot more time, drill will work harder, and you will strip some screws.

Pre-drill where needed. When wood screws are sinking into dense wood the excess scraps need a place to go. Not predrilling puts a TON of strain on drill and often will require multiple tries.

Countersink where needed. There are certain situations where countersinking save a ton of time and strain on drill. Using concrete board is a perfect example. Most concrete screws won't sink right on first try - maybe 30% if you are good. Simple dimple with a 3/8" bit save you time.

There is an art to drilling. Yes it is easy to screw in a drywall screw but there are 100s of uses for a drill and most are a lot harder. You holding the drill straight make a huge difference. Being off by 10 degrees makes a big difference - doing that consistently can make your life a nightmare on big jobs. The second part is putting good leverage (push) on the drill for harder screws. The drill should move the screw/bit around - you should be pushing it in (or drill works a lot harder).

Don't use a regular drill for masonry work that a hammer drill is for. Not only will this take you forever, but most of the time it simply won't work, ruin your drill, and your bit.

Take care of your drill. Keep it clean. I see guys leave thinset/mud/drywall mud on drills and they will wonder why rust appears or there are electrical issue...

Corded drills provide more power. I love my cordless and it's my #1 used tool but there are things it isn't mean for. When I need a ton of power I use a cheap corded drill. It works better and keeps cordless working longer.

- 47,296

- 15

- 79

- 187

-

-

-

I didn't fix it because I was not sure what you meant. Either buy or left out a couple words. – JDługosz Jun 25 '16 at 03:33

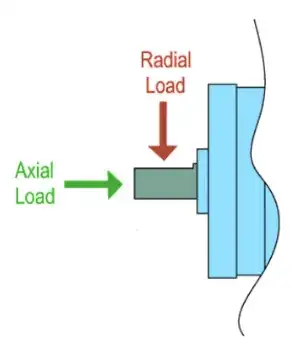

Radial loads are bad. Axial loads are good. The bearings in your drill or drill press are designed to counteract the forces in line with the drill bit. A milling machine does both, and using a drill or drill press like a milling machine will destroy the bearings quickly.

- 103

- 2

- 448

- 2

- 8

-

3Did you have to draw the good thing in red and the bad thingi n green? – user253751 Jun 24 '16 at 00:22

-

a drill bit is not designed to cut on the flute like an end mill. However you will see many folks making a hole larger by moving the drill off axis. It works but not clean. The biggest advice I Could give is to use cutting oil and slower speeds when cutting metal the goal would be to have a long chip develop this shows your speed and pressure are correct for the material being cut and the bit will last longer.

- 101,306

- 4

- 72

- 150

If you put a hole saw onto your drill, avoid going fast and always brace it well in case it catches. I have a bad wrist to show for careless hole saw use.

- 246

- 1

- 2

- 10

If you're drilling metal, use an appropriate type of bit (HSS, whatever), use some cutting lube, and drill for short periods with breaks between. Don't run the drill too fast either. If the bit overheats you'll ruin the temper and destroy the bit. Since the title of this question really should be "tell us the dumb ways you broke stuff", I'll mention that I've ruined HSS bits in maple too by drilling to fast for too long until they overheated.

If you're using a drill to drive screws, most particularly those furshlugginer phillips monstrosities, use an appropriate setting on the torque clutch to prevent camming the bit out of the fastener head and damaging both the screw and the bit. Also use the torque thingy to prevent driving screws too hard into wood, sheetrock, or whatever.

The back of the drill looks like the poll of a hatchet, but it's not a striking tool. I know, I know, why do they make it LOOK like one if it's so ridiculously fragile?! Craziness! But I learned this the hard way: You can't drive a nail with it. More subtly, you can't hammer in a screw with it either.

- 407

- 2

- 8

Drill pilot holes and gradually widen them. This saves you energy and reduces wear on your drill bits.

Always use the supplied handle to brace the drill. This keeps you from injuring your wrist if the bit catches.

All these answers are along the lines of "do these things" but the list of things to not do with a drill is infinite and includes things like "don't drill into yourself or other people" and "avoid setting yourself on fire while drilling".

- 1