I've just pulled apart an old russian washing machine to extract a couple of motors to use as in windmill generators I'm making. I don't know much about motors, so I'm kinda new to this but want to learn about it.

One motor has 4 wires coming out of it. 1 wire is copper, the other 3 I think are aluminium. The copper wire has red insulation, there's another red one, a black and a blue. There is also a 5th wire connected to the body which I'd guess is ground/earth.

I've read a few posts around the place like testing with a multimeter the resistance between the wires to find pairs.

The resistance between:

- Red(copper) & red(aluminium) wires: 19.2ohms

- Red(copper) & black: 1.4megaohms

- Red(copper) & blue: 1.3megaohms

- Red(aluminium) & black: .9megaohms

- Black and blue: 51.2ohms

- Red(aluminum) and blue: 1megaohms

So from what I've learned, whatever pair has the least resistance is connected to the Armature and therefore, the other 2 are for the field. In my case then, red and red are armature (brush?), black and blue are field

What I'm curious to know is, how would I connect these wires for using it as a generator? I saw a video of a guy connecting the 4 wires into 2 to 'induce some voltage' as he says.

If I connect mine the same (2 red wires together, and black and blue together) then connect it to a multimeter to test volts and give the motor a spin, I can see it's creating a AC voltage, but not much (.02v). I'm not using a drill. If I switch it to testing DC voltage, nothing changes when I turn the motor. So I'm assuming it is an AC motor but I really don't know. How can I be sure?

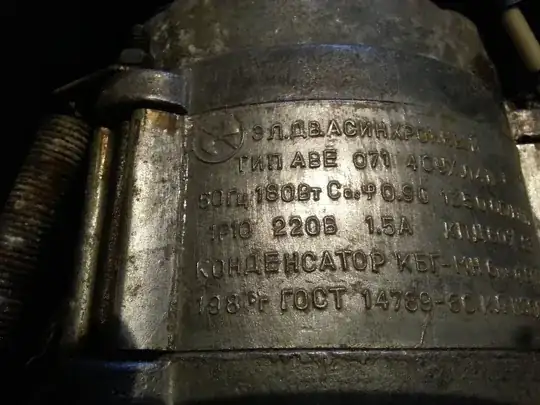

BTW, these are the details from what I've gathered reading the russian 180v, 1.5a, and I think 1350RPM. Here's a photo(s) if you happen to be able to read this:

Any tips for this would be greatly appreciated! Thanks