If you simply tape up the plastic it will fall down. It will not matter whether you use painters plastic or heavier weight stuff. Dust walls are important, more important than that is they stay up. A leak or rip in the wrong place will still let the room get clouded with dust.

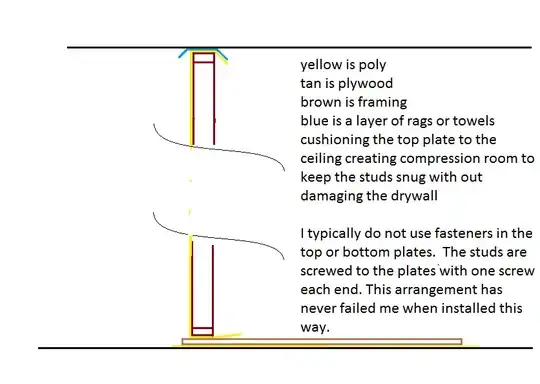

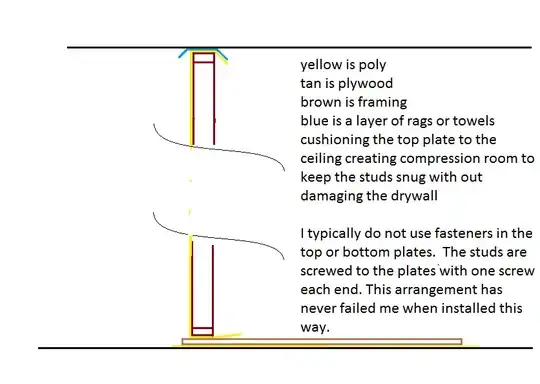

I build my dust wall with 4 mil poly and 2X4s. In areas of finished floors I use poly on the floor for spills and 1/4" plywood seamed with duct tape for durability, from dropping framing material and such. If I am using plywood protection, I build the 2X wall on the edge of the plywood. To save a lot of explanation, here is a sketch.

I have added a few pics of my last job where I built this type of dust wall, the pics were to highlight details behind the drywall after it was covered, not to highlight the dust wall, although the details show a little of the idea I am trying to get across.

To evacuate the dust I plan ahead where I can set up a box fan that runs full time while demo is going on.

This fan went in where a new window was going in, it stayed after the window was set to get the drywall dust out while sanding.

For the entrance, I do not like the zippered openings that cut into the plastic, at points in time the traffic will be heavy in and out of this space, I have tripped many times going through the zippered opening. In time I have ripped it and had dust coming out, dusting the floor, Try taping over this area again, or any area once a seal has failed. If the though is being more careful, it is easy to say, but try being careful with a large heavy item in your hands walking backwards bring in a load of materials, it only takes one time. To get past this I use a double flap of poly 4' wide at the other end of the room from the fan so the air is always drawn in through the flap door into the work space. There is a walk area outside to protect when a person steps out to keep the trash coming off the shoes. This must be strictly maintained or a trail will end up going through the house.