Why do HVAC pros mix terms like "relay" and "contactor"?

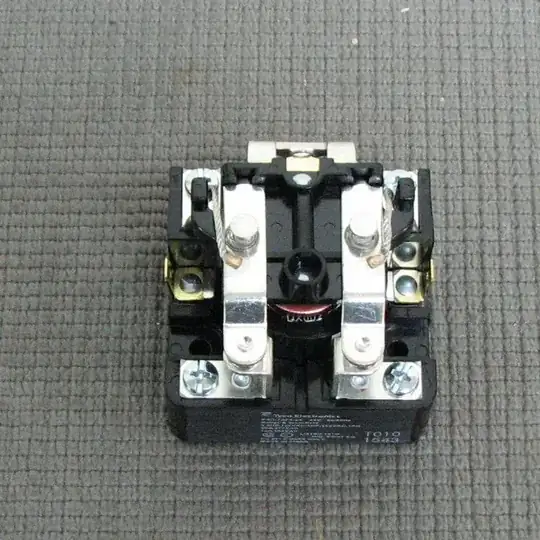

Here's an example of a 'contactor' being called a "Contactor Relay". Also, I've seen online supply houses using the terms interchangeably, as well.

Why do HVAC pros mix terms like "relay" and "contactor"?

Here's an example of a 'contactor' being called a "Contactor Relay". Also, I've seen online supply houses using the terms interchangeably, as well.

They are both magnet valves that switch electricity. They have an electric coil energized by some sort of voltage, often a low voltage. And they pull together (or apart) electrical contacts, often two or more sets of them.

The difference just boils down to the common-practice-in-industry use of words. As relays get bigger and rated for higher power operation or to interrupt large loads (especially motor loads with considerable inductive kick)... they start calling the things "contactors" instead of "relays". So to a degree, it connotes high power rating and arc suppression features such as arc chutes and magnetic blowouts*. Some even use pneumatic blowouts *.

Speaking more broadly, another characteristic of things we in archictural and railroad wiring field tend to call "contactors" is auxiliary contacts, often "bolt-on/add-on". A "relay" typically has 1 to 4 "poles" of parallel contacts of roughly equal size. A "contactor" typically has 1-3 poles actually intended to switch high power/current, and then a number of auxiliary contacts used for low power/control wiring.

An example would be, say you have a home backup system using a modern grid-forming inverter. You could use a costly 200 amp DPDT transfer switch to isolate it from the grid, but why not just use a far cheaper 200A SPDT contactor? An auxiliary contact on the contactor handles 12 volt signal voltage, and the grid-forming inverter uses that signal to know when it's safe to backfeed.

* A magnetic blowout is where the high-current path makes a loopy path in a particular way, causing it to throw a magnetic field; when the contactor interrupts and the contact tips start sizzling and arcing, the magnetic field also collapses, pulling the arc itself into the arc chute.

Where shop air is available, a pneumatic blowout is found on air-assist contactors, which have a SPDT "magnet valve" for air. When energized, supply air is routed to an air piston, which throws the big electrical contacts (and auxiliary contacts). When de-energized, the magnet valve vents the piston, which lowers via a spring. The vent is a nozzle aiming right at the arc flash, which blows the arc into the arc chute. Thus, the waste air from releasing the contactor blows the arc out.

A contactor is just that--a set of contacts to open and close a circuit. A relay is an electromagnetic device which actuates a contactor. Therefore, a relay can be described with both terms, but a contactor isn't necessarily a relay. Some are manually operated or are engaged through other mechanical means.

A manual contactor is a type of contactor whereby an operator has to activate the switch to engage the power circuit physically.

Since the knife blade switch became potentially dangerous to use, engineers came up with another contactor device, which offered a number of features that were missing in the knife blade switch. This device was referred to as a manual controller.

Obviously a manual contactor doesn't contain anything that could (or should) be called a relay.

To your actual question about pros misusing terms... blue collar types don't also tend to be as pedantic as, say, a software developer. Misuse of terms doesn't usually result in the product failing as they would in software, so harmless (if mildly annoying) habits develop and persist between folks.

In this case, though, the term is accurate. The device contains a contactor and a relay.

In practice, the terms usually refer to the way the devices are internally constructed. In this usage, a relay refers to a switch where the switching element stays connected to one of the terminals, while a contactor refers to a switch in which the switching element disconnects from both terminals. A relay often has 3 terminals per switch (common, normally open and normally closed), although the 3 terminals are not always all exposed to the user and this is less common in power relays. A contactor always has 2 terminals per switch. Both devices can have multiple switches per coil, although relays with more than 2 poles are somewhat rare, while 3 or 4-pole contactors are fairly common.

Edit: in the comments you ask specifically about the Trane RLY03346. This photo of the inside of it shows that the terminals on the top are permanently connected to the switches with 2 wires, as such this is a relay (as also indicated by the letters 'RLY' in the model name).