I have a deck joist hanger or two that I was considering replacing in-place if possible. The issue is this deck is 20+' in the air on uneven ground so supporting the joist from underneath before removing the hanger isn't that feasible. However looking at weight distribution, all the newer deck boards secured to it, spreading the weight all over the deck, would it be an issue to remove in-place and install a new one, or could that cause an issue with the joist sinking and making a mess of things? I also could probably use ratcheting straps to the next joists on either side to support from underneath I suppose if needed to distribute the weight.

I've also seen hangers that can slide over the old one and the mounting holes are in a different location, so if the experts here think that's better let me know (need the part number or link).

So is it possible to replace a joist hanger in place on 1 end without supporting the joist from below or is it not possible?

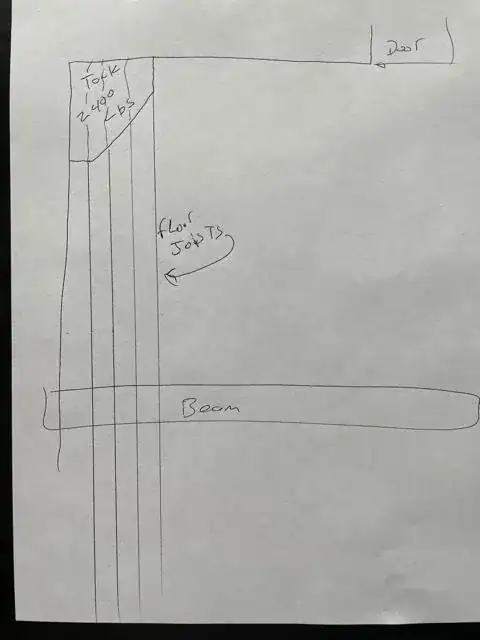

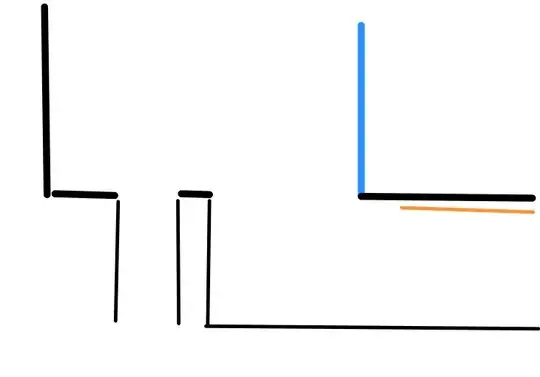

EDIT Here is the solution I ended up using which was a combination of all the advice given below. It uses (2) 4x4s as the posts, and (2) 2x4s for lateral supports that butt up against the deck boards on the backside. The rod is a solid 3/4" steel bar. The ratchet strap I'm using is good for 400lbs, but I have 1000lbs if needed. The ratchet will allow precise adjustment to be level once putting in the new bracket. The thing I like about this rig is it still allows me to work around and under it with clearance. If anyone reads this in the future there are probably a dozen good ways to do this and all the information provided useful.