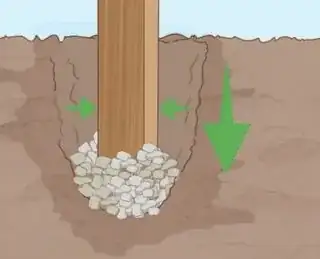

I am installing a wood railing post for an exterior railing and had planned to use the approach for fastening to a [new] concrete footing that is commonly used for deck posts. The post sits on a bracket that is elevated a couple of inches/few centimers above the concrete by a hefty steel screw that is embedded into the concrete when poured.

The tradesman working with me vehemently disagrees with this approach pointing out that a railing must withstand quite different - in particular shearing as a heavier person pulls on it - versus a deck post that must withstand primarily compression stress. The tradesman is concerned that a single bolt would not be sufficient to withstand the pulling on it.

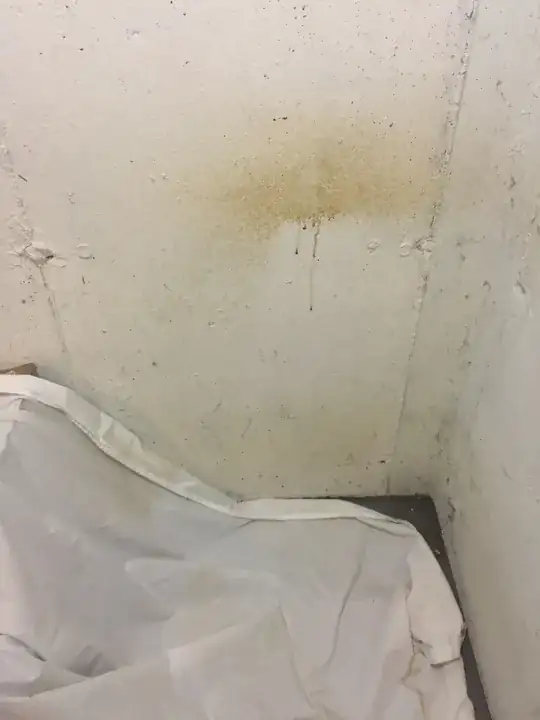

I am still leaning towards the bolt embedded into the concrete due to the concern of rot when embedding the pressure treated lumber into concrete. It will rot.

So then - does the embedded bolt possess sufficient shear strength? I believe that to be the case but do not have a reference to back that up.

Note that there are mixed results when doing a web search for:

should I encase the railing stair post into concrete

The first two results I found resulted in a "split decision" on the choice.

So, is my preferred approach of using the bolt going to be safe for that pro football player grabbing onto the railing? Or do we sacrifice some longevity of the structure by burying the post into concrete so that it's definitely not going anywhere today.. but conversely will definitely be suspect in a couple to several decades?