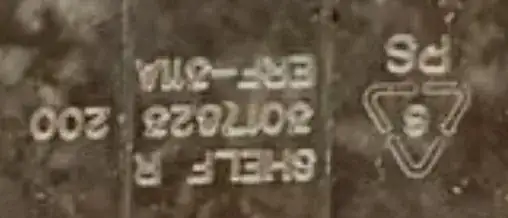

My fridge shelves cracked and broke, and although I tried a repair mentioned in a previous question, it eventually failed as expected.

Since it seems that replacement shelves are no longer sold for this fridge model (Daewoo ERF-384/385/387/388 M/A), I looked for metal bar stock as suggested in the linked QA, but it seems that aluminium bar stock of the suggested width and thickness would be more expensive than purchasing a sheet of plastic. There are vendors who (e.g.) sell 'universal' replacement shelves, and those who sell plastic cut to size as replacement for shelves. Both of these are examples, but both list the thickness of the acrylic/Perspex/Plexiglass sold as 5mm.

I contacted a local plastic supplier who can supply cut cast acrylic sheets (among others) for advice, but they were unable or unwilling to make a recommendation as to material. Is there a difference between cast acrylic, Perspex, and Plexiglass? If not, is 5mm a suitable thickness for reasonable, everyday domestic fridge shelf use? My local supplier can make sheets up to 10mm if thicker is better.

The measurements of the replacement shelf are shown below:

(dimensions in mm)

The shelf seems to be very slightly tapered and so is trapezoidal, being 10mm shorter along the rear edge where the arc is. I am hoping the local plastics supplier can cut accordingly but if not I assume (hope) the plastic can be filed/abraded to fit.

My intention is to duplicate the top-down ("2d") shape of the shelf, rather than trying to mimic the "3d" shape of it with grooves and retaining stops etc- ie end up with something flat.

I would prefer to keep the fridge, rather than replace it for want of a couple of shelves!