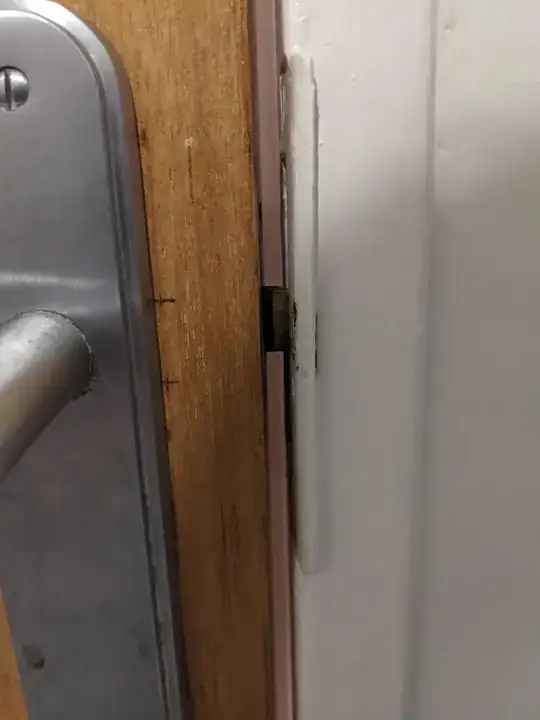

We are building a home. We selected a solid pine floor which comes prefinished. It has tongue-and-groove on the sides, but not the ends. The builder & installer did NOT cut the ends of the boards to ensure tight square butt joints, so we have a large number of but joints with out-of-square gaps. See photos.

The builder and installer said that the supplier (a third generation outfit in GA) told them they shouldn't cut the ends in order to preserve the finished ends of the boards. When I spoke with the supplier he said "I told them no such thing! They should have cut them and then used the can of finish that came with the wood to finish the cut edge." That is what makes sense to me. The builder's story doesn't make a lick of sense except that they were trying to get the work done fast and cheap.

What are the acceptable standards for installation of solid pine flooring?