I'm doing a bathroom remodel and adding a utility sink for my wife's art studio on the floor above. When we talked over the plan, I decided to go with the 2" drain they said I should use, but I had wanted to send it through an interior wall. However, they talked me into the exterior wall and said they would connect to the tub drain right where it came down. I even installed a ledger ahead of time and we talked about drilling through it for the drain.

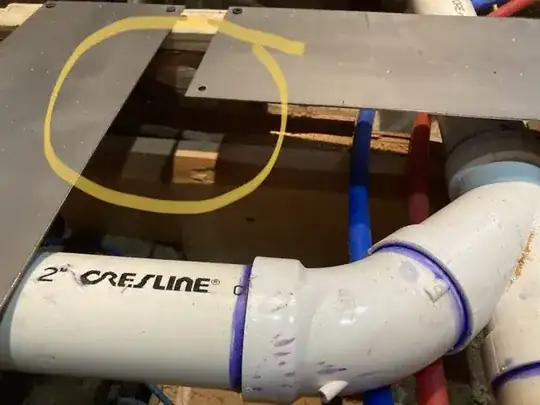

Somewhere along the line though, the plumber changed his mind and went through 2 structural 2x4s. I was shocked when I saw it. There's less than an inch of wood on either side of the hole.

What should I do? Doesn't this weaken the wall? It even blocks me from installing the other ledger I'd planned and one of the joists it goes between has a huge gouge out of it I'd planned to deal with.

Here are some pictures:

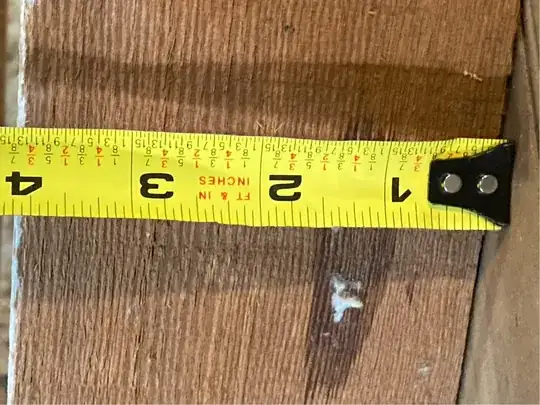

I thought I would add an earlier picture of the joist I was going to shore up. It's a little hard to see due to the shadow, but there's a horizontal chunk of wood that is missing just above the sister. My plan, before the pipe was unexpectedly routed there, was to add a ledger on either side. That joist was notched way too wide before I bought the house. Now with the pipe in the way, I'm not sure how to address this.

More pics - Adding a few more pieces for better visualization of the off-center stud hole:

Update: I just spoke with the building guy at the township construction and code enforcement office. He pointed out that given the shape of my roof, it is a loadbearing wall. I forget the name of the roof type, but it's essentially almost like a pyramid (with a wide peak). I thought this was a significant detail I should add.