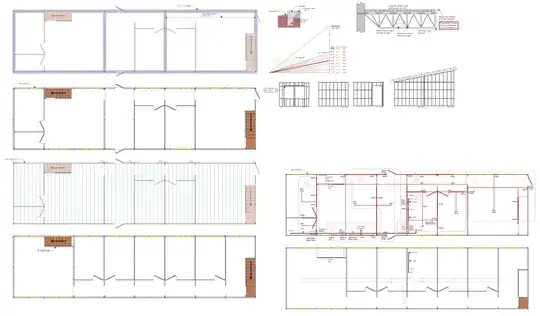

I have been putting together plans for my dream house. First an architect friend of mine said she might help, but right now she's got too much business and she hasn't even had time to look at a drawing. Then lumber prices were sky high and someone suggested I use metal. So I redrew my draft plans with metal in mind, but I keep finding a lack of information. Like span tables. They exist for wood, but I can barely find the math for calculating maximum deflections in metal. As soon as I run into any questions, I'm left in the dark.

I have been putting together plans for my dream house. First an architect friend of mine said she might help, but right now she's got too much business and she hasn't even had time to look at a drawing. Then lumber prices were sky high and someone suggested I use metal. So I redrew my draft plans with metal in mind, but I keep finding a lack of information. Like span tables. They exist for wood, but I can barely find the math for calculating maximum deflections in metal. As soon as I run into any questions, I'm left in the dark.

So I took this to an engineer in town and he said that wood construction is standard. There are fixed tables and placements that you just need to look up in the code. It's easy precisely because you don't have to do any math. Engineering a metal building is tough and the spacings, etc. used for wood won't work because the dead loads are much heavier. I might overengineer the building to support massive loads, at higher cost, but I can't prove it without the math.

An interested engineer could do the math and give me a set of drawings, but the county building inspector won't know how to read them or what to do if we have to deviate in the least. I would have to take them to the state's steel engineering expert, along with the math, to get his approval. If I change anything, we are literally back to the drawing board.

I've started looking back at my wood drawings, but even then I wanted a steel beam to go over the 20' span in the kitchen and great room. I would definitely need 2x12x20s across those expanses and not all species of wood would be strong enough. Everywhere else, I could get by with 10' spans following the length of the house.

Now that I've looked at it, I'm actually more interested in steel and especially in its anti-rot, anti-bug, anti-water capabilities. Is this all completely hopeless or is there a way to finish the construction in steel? Where do I go to get the right kind of architect or engineer?