That little plunger is called a dead latch. It requires precise and correct alignment between the door latch and the strike plate with no excuses.

The purpose of a dead latch is that if it is held in, the latch can't move. This defeats "using a credit card" to force against the latch's ramped piece to make it retract.

The strike plate, thus, must be correct for the dead latch. It must allow the latch to drop into the hole, but the dead latch not to. The best option is to use the strike plate supplied with the lock set, whose hole should be the right size so only the latch fits.

The dead latch should not be taking any damage because it should not be falling into the hole. It sounds like the dead latch is falling into the hole, and then, is bearing the full force applied against the door, including by the wind, which can be considerable.

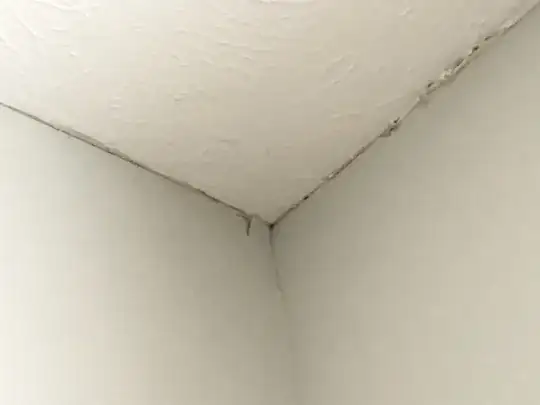

Too big a gap between door and strike plate

Part of your problem may be the strike plate being too far from the door. (I can look right at the weatherproofing and tell you that!) In that case, the beveled latch is only going partway into the hole, and that is leaving room for the deadlatch to fit also.

The latch is beveled. If the strike plate is close like it's supposed to be, the hole is only big enough for the width of the latch, and the deadlatch can't fall in. However, if the strike plate is too far away, it aligns with a part of the latch that is not as wide (since it's beveled). That leaves room for the deadlatch to fall in.

The gap between door and strike should be very close - you should barely be able to fit a credit card in there. I bet you can fit about 6 credit cards in there!

I also notice the latch is "inset" from the edge of the door. That shouldn't be. You need to shim that back out so the latch is flush or even very slightly proud of the door edge. Here, every mil matters.

^^ How it's supposed to work.

^^ Yours. Note too-big gap and too-inset latch allowing deadlatch to fall in.

That type of weatherproofing makes "closed" ambiguous

If a door is not weatherproofed, there is a well-defined point where the door is positively closed all the way. With this type of weatherproofing, after the door first contacts part of the weatherproofing, you can lean on the door harder and harder, and the door will keep closing, moving more than 1/4" additional if you lean on it hard enough. This makes correct positioning of strike plate extremely difficult, but also, all the more important. It's a mistake to set the strike so the door is too loose; first it will bear a lot of dynamic force from being loaded in both directions by the wind, and second, people who pull the door shut hard will drag the latch past the strike plate, making for very sloppy latch action... and (again) allowing the dead latch to fall into the hole if the strike plate is too far away.

You say the oval screw spaces in the reinforcement are in the wrong place. I doubt that. I suspect the weatherstripping is making you want to put the strike in the wrong place. Since you're already having trouble with the dead latch dropping in, clearly you're already putting the strike plate too far out, and it appears you are near the outer limit of that oval. I suspect correct placement will be closer to the inner limit, but this will make the door very stiff to close, and you don't like that.

Well, you're going to need to sort that out. Decide whether you want to keep this weatherstripping and place the strike so you must pull hard to close, go with other types of weatherstripping that don't interfere with a positive "closed" position on the door, or get rid of weatherstripping.

The wood may be too beat up to take screws

It's also possible that the wood "meat" the strike plate screws go into has perished from over-use, and/or the existing holes simply making it impossible to get a screw to go in the correct position (since the screw seeks the existing hole). That thrashed wood fiber needs to be drilled out and replaced with some sort of filler. I would drill it and epoxy in a softwood dowel. It needs to be about the hardness of the underlying wood, not much harder or softer (or drills will "seek" the softer material).

You could use an epoxy with filler instead of a dowel; a blend of colloidal silica and fairing filler (e.g. West System 406 and 410) would be a nice compromise between softwood hardness and strength.

I've also heard of people driving match sticks into the screw holes (NOT with the flammable heads!)

So... it sounds like the door framing has been a real "slop job" and these issues were simply ignored by past installers.

You will need to move through each issue and correct it.

- Shim out the latch in the door so it's flush, or a tick proud.

- Shim the door, or jamb, or strike base, so the door and strike are close enough to work as intended.

- Find the strike position so with the latch extended, but the dead latch retracted (tape it down), the door compresses your weatherstripping (if any) firmly for a good seal, and without allowing slack of movement.

- Remedy any issues with chewed up wood not letting you place screws correctly.