Here's some info which is applicable to the other answers that suggest using sheet metal screws. At least for steel studs, there is readily available engineering data that can be used to judge how well this will work. (TLDR: it should work fine).

Background - steel studs are manufactured to standards. So it doesn't matter who made them, you can assume they're commodity items.

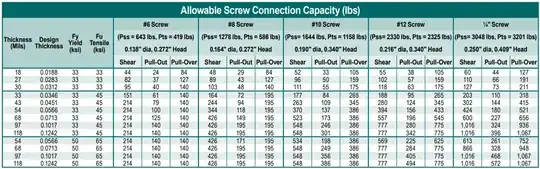

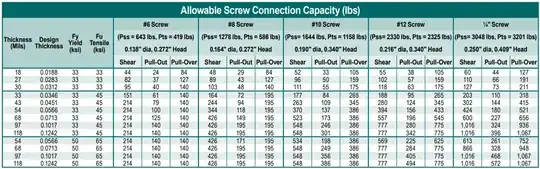

This is the "Screw Capacities" table from the Steel Stud Manufacturers Association "PRODUCT TECHNICAL GUIDE" (p.70):

(sorry that this is only in US units, not metric).

From that table, here are the allowed values for the smallest screws in the smallest/weakest stud type available:

For clarity, these are the 3 different ways in which a screw connection could fail that the table refers to:

"For self-drilling screws, there are three main modes of failure:

pullover, pullout, and shear (Fig.

6.8). In a pullout failure the screw loses its grip, while in the pullover failure the material around the screw fractures."

Now, a TV flat-mounted to the wall is mostly(*) going to exert a downwards force on the screw, which should mean that shear failure is the biggest concern. But even in this weakest-possible scenario, a single screw should survive until you put 44 lbs (20 kg) on it.

(70" TV ~= 52 lbs / 24 kg)

How many screws will attach the TV mount to the wall? At least four - thus you have 4 * 44 = 176 lbs (80 kg) capacity, at minimum. This is > 3x the 70" TV example.

Obviously this is not a real engineering estimate - just back-of-the-envelope thinking to judge whether screws would OK to use. My conclusion is that they almost certainly will be fine.

I would recommend a few things to reduce any risks from inexperience when installing, and unforeseen events (*):

Use as many screws as possible - they are cheap and probably come in a pack of 10-20 anyway. I'd fill all the holes in the mount, and in every stud it crosses over.

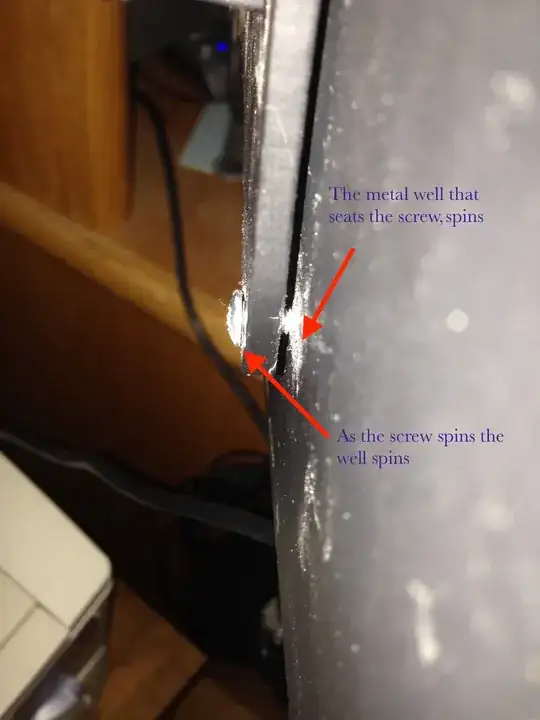

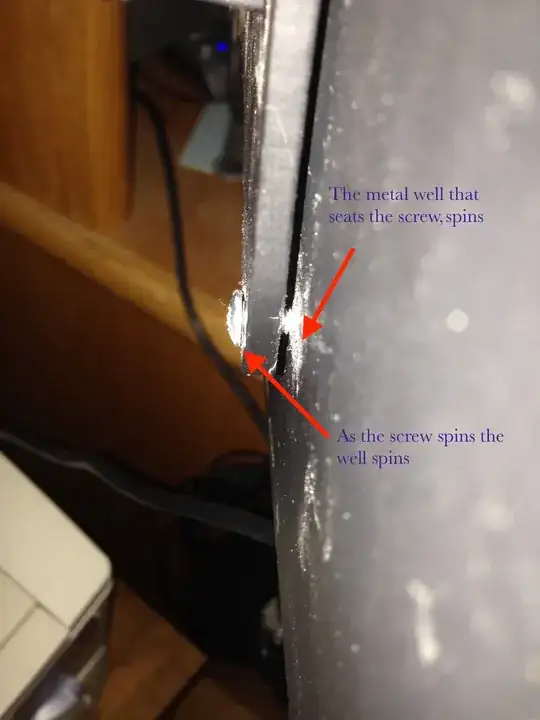

Don't underestimate screw length - you want definite penetration fully through the stud wall. If in doubt, 1½" or 2" screws seem like a good idea to cope with varying or unknown material thickness.

Consider adding washers on each screw. The TV mounting holes may have been intended for something big like a lag screw, not a small sheet metal screw.

(*) Such as a pet climbing on it, a person tripping on a cord yanking it really hard, etc.

If you have aluminum studs the details would be different (thought not necessarily a different ultimate conclusion). If I can find similar info for those or if someone can point it out, I'll edit this to add it.