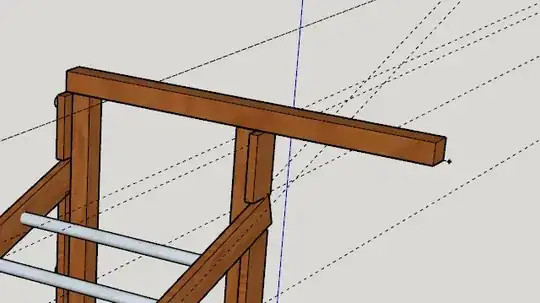

I'm looking to find the safest way to secure a 4x4 to act as a beam for rope-climbing. In the picture below, the "top" beam sits on-top of two 4x4 posts.

The rope will extend from the far right of the post, putting upward force against whatever join/fastener is selected when someone is climbing it.

Most of the 4x4 fasteners I've seen are designed to secure a post vertically and not against the direction of force being applied here.