I'm working on running some SE cable from a breaker box to a new 220V 14-50R receptacle. The old receptacle was not located within the area specified by our new electric range.

I'm working on running some SE cable from a breaker box to a new 220V 14-50R receptacle. The old receptacle was not located within the area specified by our new electric range.

I am using TYPE SE STYLE R with four 6 AWG AL wires. One wire is an unshielded ground, the others have XHHW-2 insulation. One question I have is related to the number of bends allowed in the cable. In my earlier readings of various articles I thought I saw something about a limit in the number of bends. But at that time things were very foggy to me as opposed to being just a bit foggy now.

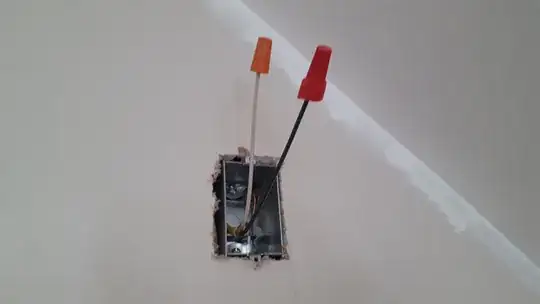

Here are a couple of pictures from different perspectives.

![Cable with Clamp in place[![][1]](../../images/3790933058.webp) ]3

]3

A reason for two of the bends is to accommodate a cable clamp which I think must be within 12 inches of where the cable enters an electrical box. The only way I could see having the clamp and reducing the number of bends is add another 2x4 which I think would then put the clamp more in line with the straight line routing of the cable. Any thoughts on this? Thanks in advance. Jim