I have a Ridgid angle grinder and a metal cutoff wheel.

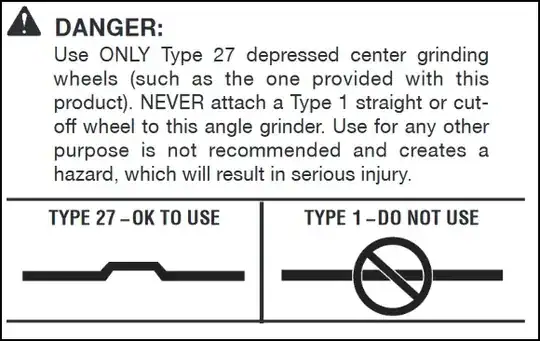

On page 7 of the manual it states:

Use ONLY Type 27 depressed center grinding wheels (such as the one provided with this product). NEVER attach a Type 1 straight or cut-off wheel to this angle grinder. Use for any other purpose is not recommended and creates a hazard, which will result in serious injury.

After reading some online forums, asking some contractor friends, and watching YouTube videos it seems that everyone simply uses a Type 1 wheel to cut metal and move on with their life.

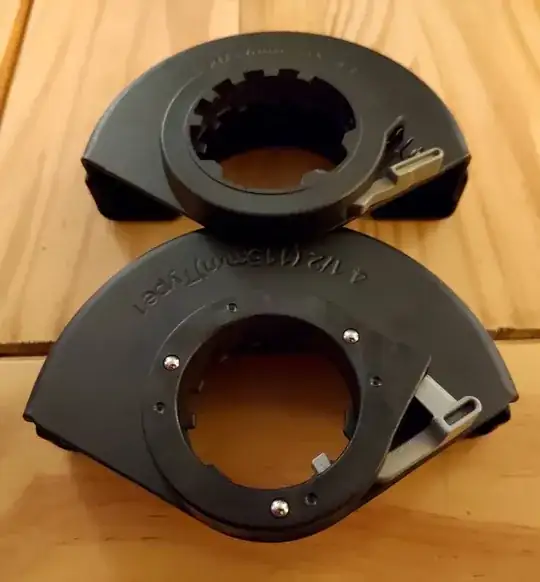

PS: I won't acknowledge the countless people that use an angle grinder without the guard. I will absolutely be putting the guard in the correct position.

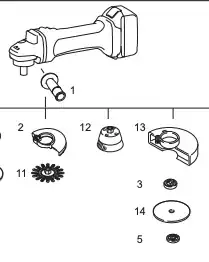

As far as I can tell I just have to reverse the clamp nut and it securely holds the Type 1 cutoff wheel in place.

Am I using the wrong tool or wrong cutoff wheel or are there simply so many more Type 1 wheel accidents that companies just try to distance themselves from Type 1?

Even the cutoff wheel packaging says "for use with angle grinders" and has a picture of an angle grinder.

Important: I am trying to solicit authoritative answers which can properly explain why one should not use a Type 1 disc. I do not wish for polling answers such as "I've done it so you're fine".