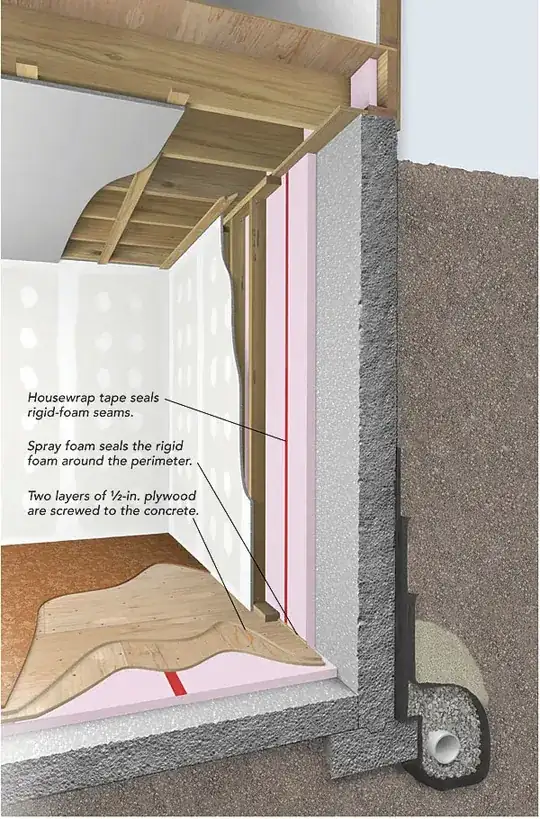

I intend to finish a part of my basement following this guideline from Fine Homebuilding and Building Science. There are two options I could come up with for installing hydronic radiant heat extrusions, and I can't decide which of the two is most ideal.

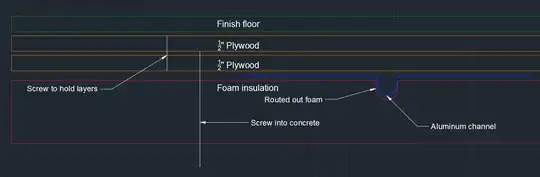

Option 1 - Route out a pathway into the insulation that would fit the aluminum channel, then cover with the two layers of 1/2" plywood, then cover with flooring

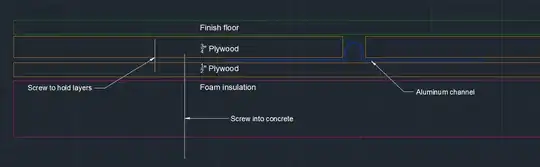

Option 2 - Start with 2" foam, put down 1/2 ply screwed into the concrete, put down aluminum channel on top of 1/2" plywood, cut strips of 3/4 plywood to go between channel, install flooring over 3/4

Option 1 is much easier to build. The foam will have some "give" when fastening the plywood against the aluminum plate, which will ensure contact and allow flatter flooring layers above. I just fear the aluminum on insulation contact, movement and directly heating the insulation. There are adhesives to secure the aluminum to the foam if that's appropriate.

Option 2 provides more "structural" support to the channel to prevent noise, as well as providing more thermal mass and more isolation from the insulation. I'm not sure if the layers of plywood will have enough "give" to encapsulate the aluminum track without causing the surface to bow.