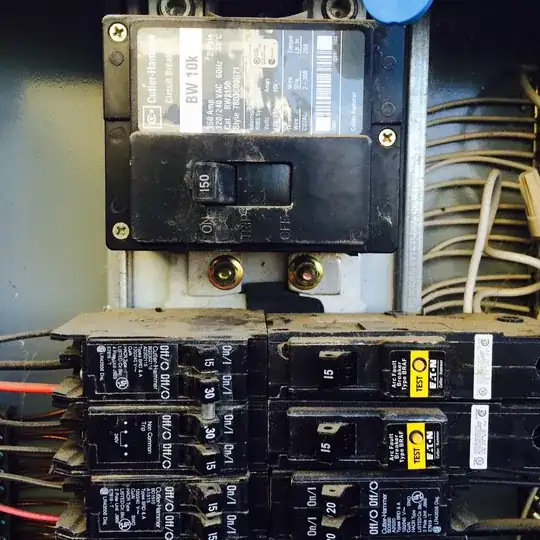

I am looking into installing a sub panel in my basement which will be used to feed electrical circuits to the basement that is currently unfinished. I have an 150 amp main panel and was thinking of installing a 90-100 amp sub panel. I do however have a few questions:

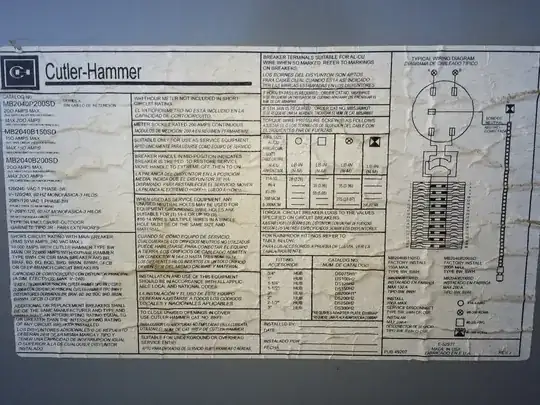

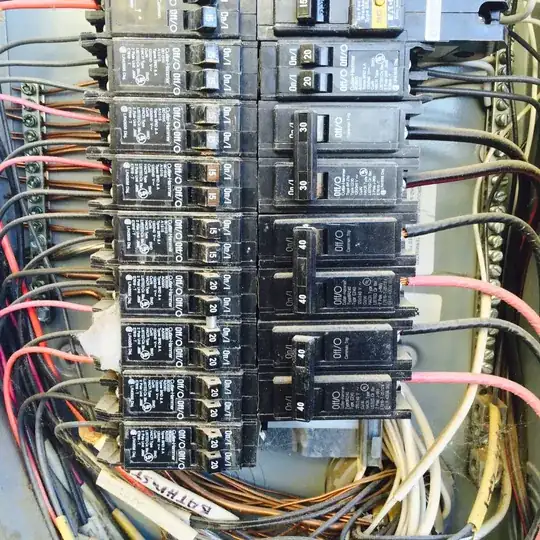

1) Since I do not have any breaker space, I am wondering if there is anyway to replace breakers or shuffle things around to make space? I've included a image below of my panel if it helps anyone make recommendations.

2) Do I need to ensure I use the same brand breakers? I assume yes...

3) Is 100 amp too much for the sub panel in the basement given the main panel is only 150 amps? I plan to have some lighting/receptacle circuits as well as baseboard heaters.

4) What is the proper gauge for the feeder wire? 2-2-2-4 enough for 100 amps? My city uses 2011 national electric code

Any help is appreciated.