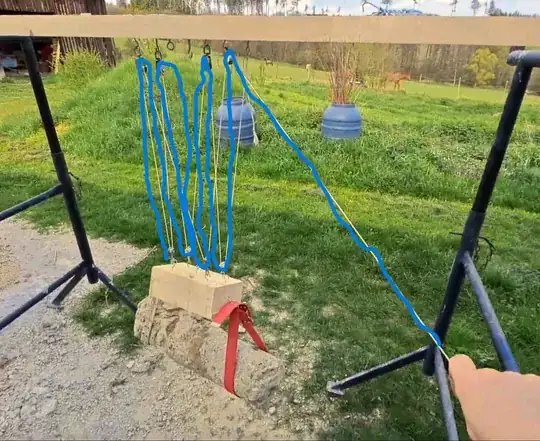

I am trying to make a portable pulley system to lift heavy stuff. I made the following prototype using 8 individual pulleys:

When I pull the rope, the load should seem approximately 8 times lighter since there are 8 shortening per one lengthening rope segment.

However, the load doesn't seem dramatically lighter. If the concrete block weighs 30 kg, then I should be able to lift it with around 5 kg of force. I haven't measured it, but it seems that I need to pull much more strongly.

At first, I tried an 8mm diameter polypropylene rope. This didn't work at all. When I pulled the rope, it was as if all but the first two pulleys were actually moving. Oiling all of them didn't help, so I tried a thinner and probably less elastic rope. The results are not ideal, as you can see in this video.

I have no idea where the most force is lost. There is the stretching and bending of the rope, the pulley wheels rotating, the wobbling of the load, and that's pretty much it. What is the most likely problem? Does it make sense to get pulleys with ball bearings? Or a different rope?