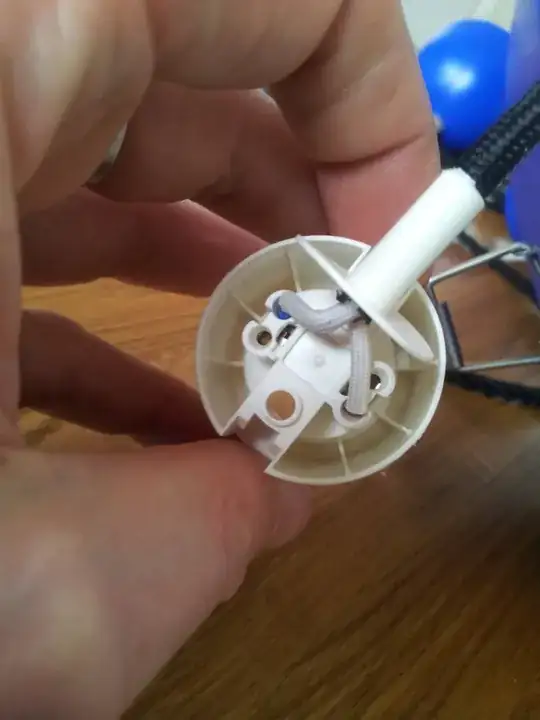

The wire on my lamp is too short, so I'm trying to replace it. The fitting/fixture (what's the correct term?) however doesn't play nice: I can't see the correct way to remove the old wire (and still be able to insert the new one).

I'm not seeing any screws at all, so it must be some sort of clip thing. I'm not too comfortable applying too much pressure to the plastic, as it might bend/break, before I know I have the correct point to insert my screwdriver.

Some shots (I can provide more obviously):