TLDR: #12 aluminum for 15A is correct. Use lug connectors, not purple wire-nuts. Favor metal boxes.

Wire sizes

The wire sizes are a physical diameter and do not reflect current capacity. #12 aluminum is correct for a 15A circuit. Aluminum is 1/4 the weight of copper, and being so light it needs more volume of wire to carry the same current. By -2 wire sizes as a rule. You have to get used to this.

The thing about aluminum

Look inside your service panel. See the main lugs where power comes in? See the neutral bars and ground bars if present? Notice how they are silver colored. Tin-plated brass, right? No. Tin-plated aluminum.

Aluminum has different thermal expansion than copper. This works in aluminum's favor when it's a lug - making aluminum lugs the "universal donor", working well with both. Copper lugs, on the other hand, do not play nice. This was not well understood when in the 1960s, the copper shortage came on fast, and UL was pressured by government to quickly approve receptacles and switches for aluminum wire. Manufacturers did minor tweaks and UL rubber-stamped it. Mistake.

Since then, this has been fixed (over-fixed?) with the "CO-ALR" rating for switches and receptacles. Check one out sometime: it's not even aluminum, it's a rare-earth metal. You can attach aluminum directly to those and do not need to pigtail.

However, copper wire connections were failing on copper and aluminum lugs. Why? Research in the 2000s turned up that screw torque really matters, even on the little stuff. (Electricians had always torqued the big stuff, note aluminum heavy feeder never had a problem). Testing at trade shows showed electricians couldn't hand-torque any more accurately than their business manger, spouse or lover! So in 2014 NEC was amended to require torque screwdrivers on darn near everything. Mind you, all this is copper, but in the 70s and 80s, nobody was torquing small aluminum connections either. Hmmmm!

All together, this gives us a pretty good road-map for handling aluminum smartly:

- Use lug connectors whose bodies are made of aluminum (universal donor)

- Set the torques correctly with an inch-pound wrench.

Purple wire-nuts are not reliable. Use lug connectors.

You need go no farther than Google image search.

But based on the above, that's not really a surprise. The purple twisters are just a minor tweak on regular wire nuts (the very thing that did not work in the 1960s with receptacles). It doesn't manage aluminum's thermal expansion differences, and certainly doesn't leverage it to advantage. There is no way to set its torque properly.

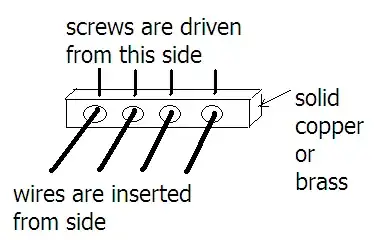

But lug connectors (like Alumiconns) leverage what works: they are lugs made of aluminum (basically your panel's neutral bar, just adding a plastic insulation box). You can torque them to the correct value for more confidence still.

Alumiconns work for 2-3 wires. For 4 or more, use another product: ILSCO's "Mac Block Connector". This has 2 larger holes, but each hole can take 1-4 copper wires, or 1-3 aluminum wires.

The largest such "lug connector" is Polaris, but not useful here (it only takes 1 wire per hole and very costly. Generally used for 4 AWG or larger panel feeder but only in unusual cases.)

By the way, local stores cheaply sell "accessory ground bars" for retrofitting into service panels, which are more of the same - and are rated for typically 2 wires per hole. I'm not saying you should buy long ones and cut them up to make "bare Alumiconns", but see below.

Metal boxes vs. plastic

I gather from the rust on those nails that you're just using old boxes you had lying around. They're not fit for the job, since you don't want to be nailing to a joist with a finished ceiling below it.

If you're going to buy new boxes for that job, buy metal. Why? We use junction boxes for specific reasons. Metal boxes are better at every one of those reasons. It contains arc fires better, it won't burn itself even if heat is applied to it, it contains arcing, and if a hot wire contacts it, it will assure the breaker gets tripped like it's supposed to.

For cable clamps, I just buy the cheapie boxes with knockouts, and use Romex cable clamps designed to go into those knockout holes. They're cheap. If you want built-in Romex clamps without high cost or wacky mounting flanges, you have to shop a little, especially since big-box stores do not carry good selection even on a good year. But my mainstay box is a basic 99 cent 4x4x1-1/2" drawn steel box with no flanges. It has a number of mounting holes fit for short drywall screws, but you can drill your own, anywhere but a knockout! Can't do that on a plastic box, they're too flimsy.

One or two of the holes is tapped specifically for a #10-32 ground screw. (-32 fine thread mandatory for electrical contact). They sell green screws that are ideal, but remember those panel ground bars I mentioned? They do not look out-of-place in a metal box. Aluminum grounds - solved!