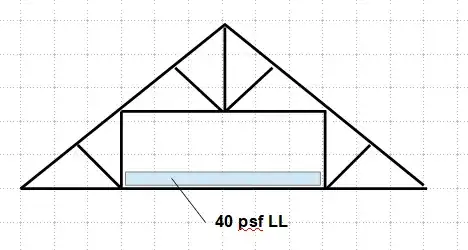

How much load can this garage loft handle?

The garage is 24' wide. The floor of the loft is 2x10s 24" OC. Those are 2x6s to the left of the plates (the 2x10s run all the way from those left plates to the right wall). All the vertical lumber is 2x4s. 2x6s under the garage roof. The garage walls are 16" OC.

I'm hoping to move some power tools up there and grow that space into woodworking shop. But I'm not sure if the space will support the added weight (or if it'll be a good idea... I'd much rather have a shop on the concrete pad and without having to climb stairs... but that's another topic).

I understand any advice given on this site is not legally binding. I'm just looking for an informed guess.