Rather than debate the best way to bridge this defect, I'd like to highlight the question whether it should be bridged:

Some electronic components and devices fail "safely" and others fail "unsafely". Those that fail unsafely require a back-up mechanism to effectively achieve a safe fail. That trace may be precisely such a provision.

Consider, for instance, capacitors that can blow and short, or blow and open. Similarly, transistors & switches can fail by opening or by shorting.

Sometimes the open-fail is preferred, and sometimes the close-fail is preferred. Which one is required depends entirely on what goes on elsewhere in the circuit or system: what is the overall effect of as an open and what is the effect of a close?

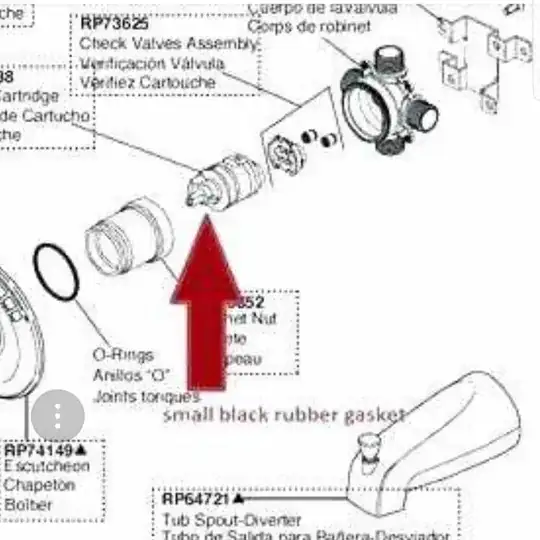

Consider the similar question, whether a valve should break open or break closed? The answer cannot be provided in isolation; it could depend on whether it is for a gas line or a sprinkler system.

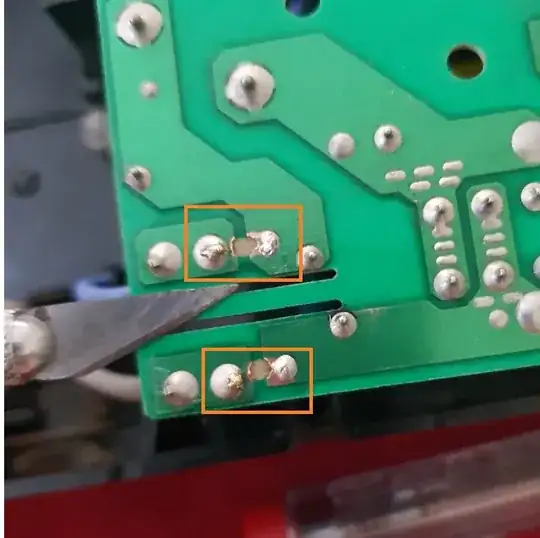

Back to the stove: that trace fuse may have been deliberately designed for that spot in the circuit. It blew because of a failed component or sub-system (a transistor, a relay, capacitor), and that component possibly failed unsafely. The fuse may have been specified there to prevent consequential damages: a further current surge (fire), an exposure to high voltage (electrocution), or an uncontrollable over heating (toxic fumes).

If it was human mishandling that caused a fuse to blow, and the cause is now removed, then replacing a replaceable fuse would be fine of course as a first attempt to repair.

But if the mishandling caused a different component to fail, as a result of which the trace blew, then jimmy-rigging it will only expose the user to the mitigated secondary hazards (fire / electrocution / toxicity).

The (e-)waste in such a catastrophic event pales against the e-waste from preventative repair or maintenance.

Given that this trace that blew was not marked as a fuse, take it as a hint that fixing the fuse is not to be attempted. Rather, the entire board and stove should be inspected by a qualified technician who is insured to take on the liability of a mis-diagnosis.