TL;DR: Other options (described below) include:

- (1) Chuck bolt directly into drill.

- (2) Cut slot in bolt and use screw driver.

- (3) Cut flats on bolt and use socket driver.

- (4) Use two nuts to provide gripping surface.

- (5) Destructive brute force with a hammer.

- (5b) Destructive brute force with a crowbar.

- (6) Cut the bolt flush to the wall.

- (7) Keep the bolt and use it for something else.

I second the vice grip solutions (definitely simple with a good success rate, and my preferred approach) -- as well as the welding technique you mentioned (not generally accessible though), but here's a few other "tricks" I've used in similar situations that can sometimes be easier than the vice grips, especially if you have a socket wrench, power drill, or impact driver to help you out, or if you don't have vice grips.

(Btw: You're not going to find nuts to fit perfectly on this bolt, but, I've mentioned nut-based techniques anyways as a general technique for other similar situations.)

Trick #1 - Chuck bolt in drill

If all you have is a drill (or an impact driver with a collet chuck):

Just chuck the bolt directly into your drill. Tighten the chuck down real good and try to unscrew it.

It can be hard on the chuck, especially if you've got the bolt in there slightly off-axis, but, with a decent tool you can generally get away with this every once in a while with no harm done. It can be your dark little secret.

If the threads cause problems here and you've got a way to grind or sand them off, you could take them down a bit first. If you cut three small flats like a triangle, it'll make any chuck very happy. If your drill's chuck is harder than this bolt (which it probably is), it'll probably wear them down a bit, too. If grip is still an issue, or you need to protect the chuck, wrap some sandpaper or something similar around the bolt first (rough side towards bolt) and chuck over that.

Trick #2 - Cut slot in bolt

Tools needed:

- Something to cut a slot in the end of the bolt with, for example:

- A hack saw.

- A Dremel with a cutting wheel (my preferred tool for this).

- An angle grinder with a thin cut wheel.

- Something to unscrew flat slots with:

- A screwdriver with a nice wide handle for leverage.

- A drill with a flat screw driver bit.

- An impact driver with a flat screw driver bit (my preferred tool).

The idea here is to simply cut a slot in the end of the bolt to turn it into something you can unscrew with a screw driving tool:

Use your cutting tool of choice to cut a horizontal slot through the center of the end; wide enough to get whatever screw driver into it. Now you've turned the bolt into a big screw, and you can use your screw driver to remove it.

Pro-tip: If the metal of the bolt is too weak and you find that the areas next to your slot are bending outwards; find a nut that fits the bolt and screw it on after cutting the slot. This will reinforce the metal and you should have no problems (unless you break your screwdriver bit, of course).

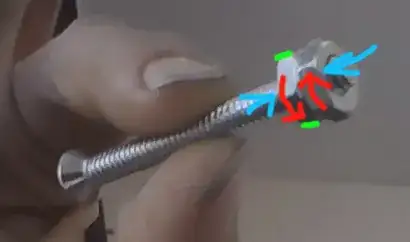

Trick #3 - Cut flats on bolt

This is like trick #2 but for if you have a wrench instead, and you have a way to grind metal flat (you might not have the tools to cut a slot). It's also useful if the bolt (or your screw driver bit) is to small / weak for #2. For this, tools needed:

- Something to grind a flat on one or two sides of the bolt with, for example:

- A Dremel with a grinding wheel.

- An angle grinder with a grinding wheel (my preferred tool for this).

- A flat file.

- A solid flat object (e.g. scrap of wood) with some low grid sand paper on it.

- Something to unscrew a flatted bolt with:

- A socket wrench (my preferred tool for this).

- A screwdriver with a socket driver bit and a nice wide handle for leverage.

- A drill with a socket driver bit.

- An impact driver with a socket driver bit.

- A crescent wrench, or some kind of adjustable wrench (not necessarily vice grips).

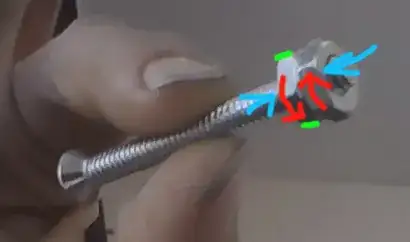

The idea here is to grind flats in the sides of the bolt (red highlight) so you can grab it with one of your socket tools or wrench, then unscrew it with that:

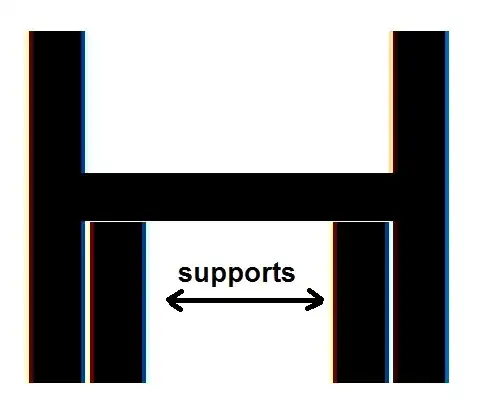

Trick #4 - Use two nuts

This one only sometimes works but can be handy if your set of tools is limited. Tools required:

- Two standard hex nuts that fit on the bolt. They don't necessarily need to be hex nuts, just two things with flat sides and threads; like maybe a hex nut and a wing nut or a t-nut, etc.

- Something with leverage to grab and twist the two nuts with (ouch...). Wrenches, etc.

What you do here is:

- Screw both nuts onto the end of the bolt.

- Now try your hardest to unscrew the first one while screwing the second one (or holding it steady). What you want to do here is basically tighten the two nuts against each other as hard as you can.

- Now, you can use first nut to unscrew the bolt. With a little bit of luck, and physics on your side, this can work provided that the friction the two nuts are exerting on the bolt threads is stronger than the torque required to remove the bolt.

TODO: better pic

Trick #5 - Brute force hammer

This one generally ends up being destructive but is sometimes your only option. Essentially, just brute force it out then patch up the hole. You'll need:

- A hammer or other blunt object.

- Materials to patch up the hole with.

This is basically what you're imagining. Just whack the bolt until it either rips itself out of the wall, or loosens enough that you can pull it out.

A slide hammer (sort of like a reverse hammer) with a nut on the bolt to pull against could help here, too, although that's a relatively uncommon tool.

Success with this is limited but can work if the wall is soft or brittle, and if you don't care about the hole.

Note that depending on the size of the bolt and the properties of the bolt and wall, you have a risk of doing a fair amount of damage here, so you have to weigh the possible outcomes here first.

As an alternative form of the above, if you can't / don't want to rip the bolt out, but the wall is weak enough to give and there's hollow space behind the wall, sometimes it's easiest just to bang on the end of the bolt with a hammer and pound it into the wall, letting it fall into the space behind the wall, where it can spend the rest of its life thinking about philosophy or the cosmos or something. At least until some random contractor finds it 30 years from now.

Trick #5b - Brute force prybar

Another form of that, if you have a nut, is to put the nut on the bolt almost to the wall, then attempt to use a crowbar or similar object between the nut and the wall to rip the bolt out with leverage.

There are other options to gain leverage here, too. If you don't have a nut, for example, you could try leveraging against the threads themselves using the V groove of a crowbar or the back of a hammer, etc. Anything you can think of to get a bite.

The difficulty with this one though is it's ideal if you can exert a force straight out along the bolt. If you come at it from the side (which is sometimes the only option, though) it can be harder to pry it out or easier to damage the wall.

Trick #6 - Just cut it off

The true IDGAF technique. You'll need:

- Something that can cut a bolt, such as:

- Hack saw

- Angle grinder

- Dremel

This one is simple: Cut the bolt off flush with the wall. That's it.

You'll be left with part of a bolt in the wall, but at least you won't have a big hole to fill.

It's not ideal but sometimes it's just all you need.

Trick #7 - Keep and repurpose it

Not sure if this even worth mentioning but; if the bolt isn't in the way, you could always just hang your coat or a painting or something on it. :D

Anyways, hopefully those help. I use the vice grip method frequently, but I've also used all of the above at one point or another.

PS: Like I said, I just wanted to add some alternatives; but re: the vice grips, if you don't own a set already, IMHO it's worth going out and buying some just for this bolt. It's a very useful tool to own in general.

]

]