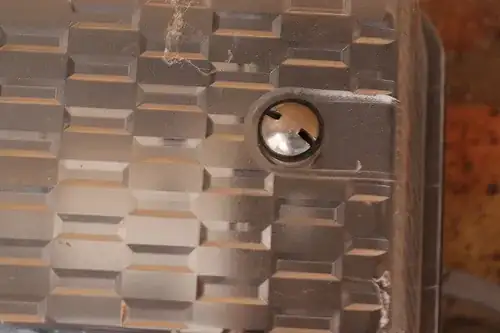

A previous owner fitted the light fitting pictured above, and has not left me a tool to remove the bolt. The bulb has blown so I need to get in to the unit. The head diameter is about 12mm and the gap between the two notches is about 6mm. I would like to remove it with some technique involving more finesse than simply smashing up the fitting and/or drilling out the bolt.

I hope someone can recognise the bolt and give me a search term which will let me cheaply buy a bit for this bolt from somewhere like Ebay UK.