Our home in Toronto was built in the early 70s with aluminum wiring. Since we are doing a bunch of renovations we took the decision.to replace the existing aluminum wiring with copper wiring.

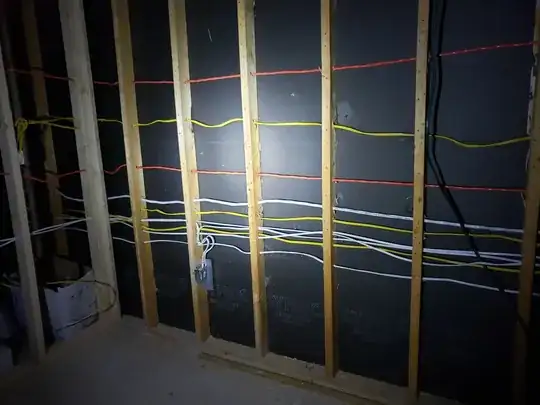

The electrician has created multiple holes in the wall studs to run the new wiring (pls see attached pics). According to him as per code he can only run a single cable through each hole. The studs look a bit like Swiss cheese and we wanted to get the opinion of the forum experts. EDIT: Please note this is an exterior wall

Is he right? Is there not a better way of running the wires? Should wires be protected by metal plates across the studs to prevent damage from screws/nails? Any other things we should be aware of or pointers you can share...