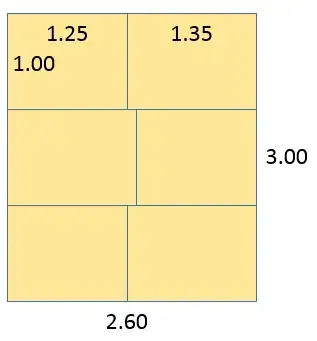

I'm designing a big door -- a rectangle sized 3*2.6 meters. (7.8 square meters).

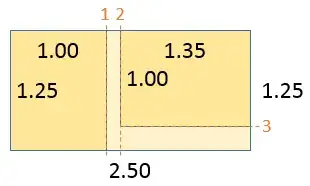

Given that the material I'm going with is OSB, which comes in 2.5*1.25 m. (3.125 sq.m.) sheets. Is there a tool/method to devise a cutting plan that'd use the least number of polygons to cover the rectangle?

UPD: Inspired by the answer:

The smallest I've got to is with 5 rectangles cut out from 3 pieces of OSB: